Formply vs Plywood: The In-depth Exploration

Understanding the Basics

Formply and plywood, at first glance, might seem quite similar. Both are engineered wood products, designed for strength and versatility. But, the devil, as they say, is in the details. While they share some fundamental attributes, their applications, benefits, and characteristics set them apart.

Historical Context: A Brief Overview

Engineered wood has shaped human civilization for centuries. From ships to shelters, these materials have played a pivotal role in numerous innovations. Formply and plywood have inherited this rich legacy, evolving to suit contemporary needs.

The Distinctive Characteristics of Formply

Toughness Meets Durability

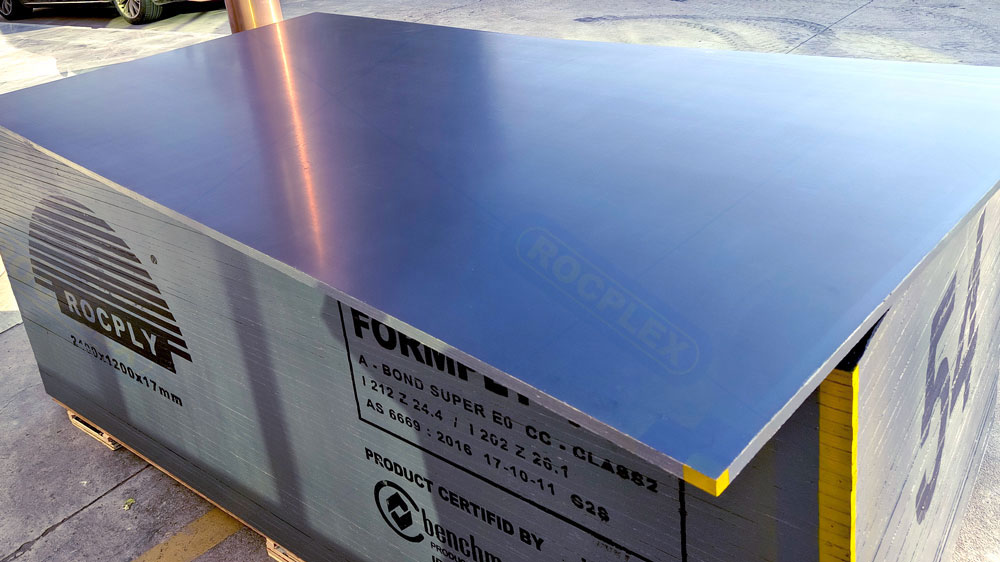

Formply, as the name suggests, is mainly used in concrete formwork. The reason? Its impeccable strength. Designed to withstand heavy loads and resist moisture, it’s an ideal choice for the harsh conditions of construction sites.

Aesthetics? Not the Primary Concern

Unlike some other woods, formply isn’t typically used for its looks. Its dark, often black, phenolic film face is practical rather than pretty. It ensures the surface is smooth, reducing the chances of concrete adhering to it.

Plywood: The Jack of All Trades

Versatility at its Best

Plywood is celebrated for its adaptability. Be it in furniture, flooring, or even in crafting, its presence is omnipresent. The layers of wood veneer, glued together, give it a unique balance of strength and flexibility.

A Canvas for Creativity

One of the most appealing features of plywood is its aesthetic versatility. With various finishes available, it can be tailored to complement a myriad of design visions, making it a favorite among interior designers and DIY enthusiasts alike.

Formply vs Plywood: Core Differences

Intended Use and Application

Formply thrives in the challenging world of concrete formwork. It’s built to endure pressure, moisture, and repeated use. Plywood, on the other hand, finds its calling in a broader range of applications, from construction to cabinetry.

Appearance and Finish

While formply leans heavily towards function over form, plywood offers a broader spectrum of finishes, catering to both utilitarian and decorative needs.

Cost Implications

Given its specialized nature, formply tends to be pricier than its generic plywood counterpart. However, in applications where durability under duress is crucial, formply offers excellent value for money.

The Pros and Cons Breakdown

Understanding the strengths and weaknesses of each material is crucial when considering formply vs plywood for your projects. Let’s delve deeper into the benefits and drawbacks of each.

Advantages of Formply

Durability in Tough Conditions

Formply boasts a higher resistance to water, moisture, and harsh conditions. This makes it especially suited for environments like construction sites where it can endure the elements.

Excellent Load Bearing

Given its strength, formply can bear substantial loads, making it a top choice for concrete formwork.

Reusability

Despite its higher initial cost, formply can be reused multiple times, which can translate into cost savings in the long run.

Disadvantages of Formply

Limited Aesthetic Appeal

Formply isn’t made for its visual appeal. If aesthetics are a priority, it might not be the first choice.

Cost

The specialized nature of formply makes it a more expensive option compared to regular plywood.

Advantages of Plywood

Versatility in Applications

Plywood is a jack-of-all-trades. From furniture-making to home construction, it’s a go-to for a variety of applications.

Aesthetic Flexibility

With different grades and finishes, plywood offers a canvas for creative expression, allowing it to fit into numerous design aesthetics.

Cost-Effective

For many applications, plywood offers an affordable yet durable solution.

Disadvantages of Plywood

Susceptibility to Moisture

Standard plywood can warp or delaminate when exposed to prolonged moisture, making it less suited for outdoor applications without adequate treatment.

Not Suited for Heavy Loads

While sturdy, plywood isn’t ideal for heavy-duty applications like concrete formwork.

Which Is Right for Your Project?

In the debate between formply vs plywood, it’s essential to assess your project’s needs. If you’re delving into a construction project requiring a material to withstand heavy loads and resist moisture, formply is your ally. But if you’re working on interior design, crafting, or any application where aesthetics and versatility hold more weight, plywood becomes the natural choice.

Real-life Applications

Choosing between formply and plywood becomes clearer when we dive into real-world scenarios. Let’s explore some common projects and which material proves more beneficial.

Formply in the Construction World

Building Foundations and Frameworks

One of the key areas where formply excels is in construction settings, particularly for creating robust concrete frameworks. Its strength and resistance to moisture ensure that the structure remains intact while the concrete cures. This is a realm where standard plywood would falter.

Outdoor Structures

For outdoor fixtures, like benches or temporary stalls, formply’s durability against the elements comes to the fore. It withstands the onslaught of weather changes, ensuring longevity.

Plywood Takes the Home Front

Furniture Crafting

When crafting a sleek coffee table or a chic bookshelf, plywood is usually the chosen material. Its smooth finish, combined with its adaptability to staining and painting, allows designers to achieve the desired aesthetic look.

Interior Design and Decor

Plywood’s flexible nature makes it a staple in interior design. Whether you’re aiming for a rustic charm with untreated plywood or a polished modern look with veneered plywood, the possibilities are vast.

DIY and Crafting

For hobbyists and DIY enthusiasts, plywood offers a canvas for creativity. Its affordability and accessibility make it a favorite for countless projects, from crafting toys to creating art pieces.

Sustainability and Environmental Concerns

When discussing formply vs plywood, an increasingly important consideration is their environmental impact.

Formply’s Environmental Scorecard

Given that formply is often used in large-scale construction, sourcing it from sustainable forests becomes crucial. Many manufacturers are now ensuring that their formply comes from responsibly managed forests, reducing deforestation concerns. Moreover, the reusable nature of formply means fewer trees are cut down in the long run.

Plywood’s Green Credentials

Plywood too has its green credentials. Many plywood manufacturers are adopting sustainable forestry practices. The production process of plywood is also relatively efficient, with fewer wastages. And given its widespread use in homes and furniture, choosing sustainably-sourced plywood can make a significant positive impact.

Expert Tips for Working with Formply and Plywood

Both formply and plywood have their unique characteristics, and understanding how to handle and work with them can significantly impact the outcome of a project.

Formply Handling Tips

Store Flat and Dry

Always store formply flat to prevent any bending or warping. It’s also critical to keep it in a dry area as prolonged exposure to moisture can reduce its longevity, even if it’s designed to resist water.

Use the Right Tools

For cutting formply, use a circular saw with a fine-tooth blade. This ensures clean cuts without splintering the edges. Also, using a high-quality adhesive specifically designed for formply can improve the bond and longevity of joined pieces.

Reuse with Care

One of the benefits of formply is its reusability, especially in construction. However, inspect the sheets carefully for wear and tear before reusing. Over time, even the best formply can show signs of degradation.

Plywood Handling Tips

Sanding for Smoothness

While plywood often comes with a smooth finish, sometimes it requires a bit of sanding, especially if you’re aiming for a polished look. Using a fine-grit sandpaper ensures the smoothest finish.

Avoid Overloading

While plywood is resilient, it has its load-bearing limits. It’s crucial to ensure that you don’t overload shelves or structures made from plywood to maintain integrity.

Edge Treatment

Plywood edges can be prone to splintering. Consider edge banding or veneering the edges for both aesthetics and to prevent wear over time.

Making the Right Choice for Your Project

Formply and plywood both have their set of advantages. The key to maximizing these advantages is understanding the specific requirements of your project.

Deciphering the Needs

For projects demanding moisture resistance, especially in an outdoor setting, formply might be your go-to. Its durability ensures it stands the test of time in challenging conditions. However, for indoor applications, especially where aesthetics play a significant role, plywood’s versatility and finish options can be more fitting.

Cost Considerations

Often, formply tends to be a bit pricier than standard plywood due to its enhanced features. However, consider the long-term benefits. In scenarios where you’d require replacing standard plywood more frequently due to wear and tear, investing in formply might be more cost-effective in the long run.

Future Trends: The Evolving World of Wood-Based Panels

With the construction and furniture industries continuously advancing, the competition between formply and plywood isn’t stagnant. Innovations and evolving needs are influencing how both materials are perceived and utilized.

Sustainability and Eco-friendliness

One of the most significant trends in the wood industry is the shift towards sustainable practices. Manufacturers are now more conscious about sourcing materials responsibly. Both formply and plywood producers are gearing towards more eco-friendly production processes, ensuring minimal wastage and more sustainable logging practices.

Recyclability

Formply, with its specialized resin coatings, was once seen as less recyclable than its plywood counterpart. However, new methods are emerging that allow for the efficient recycling of formply, ensuring it doesn’t end up in landfills.

Technological Advancements in Production

Modern machinery and technological innovations are enhancing the quality of both formply and plywood. With precision cutting tools and advanced pressing techniques, sheets are more uniform, sturdy, and offer better finishes.

Customizability

Another trend is the rise in demand for customized solutions. Whether it’s unique veneers for plywood or specialized coatings for formply, users want materials tailored to their specific needs. Manufacturers are responding with a wider range of product offerings.

Health and Safety Considerations

As we grow more health-conscious, the materials we use in our homes and workspaces are under scrutiny. Concerns about volatile organic compounds (VOCs) and other harmful emissions are shaping the formply and plywood industries.

Low VOC Products

Manufacturers are now producing low VOC variants of both plywood and formply. These products are not only better for the environment but also ensure healthier indoor air quality.

Fire-Resistant Variants

Safety is paramount, and the demand for fire-resistant formply and plywood is on the rise. These specialized sheets are treated to resist combustion, making them ideal for specific construction applications and ensuring added safety.

Formply vs Plywood Unveiled

The “formply vs plywood” debate is more than just a comparison of two materials. It’s about understanding the nuances of each, their strengths, and where they fit best. As the construction and design landscapes evolve, so do these wood-based panels, adapting to new challenges and meeting user demands. Whether you’re leaning towards the durability of formply or the versatility of plywood, it’s clear that both have a significant role in shaping the future of building and design. As we move forward, informed choices based on the latest trends and knowledge will ensure that we get the best out of both worlds.

Post time: Oct-29-2023