What Makes Formply Plywood So Special?

Construction professionals are always on the hunt for materials that offer the best of both worlds—strength and versatility. Formply Plywood does just that. This engineered wood panel, often described as a builder’s dream, is everything you’d want in a construction material.

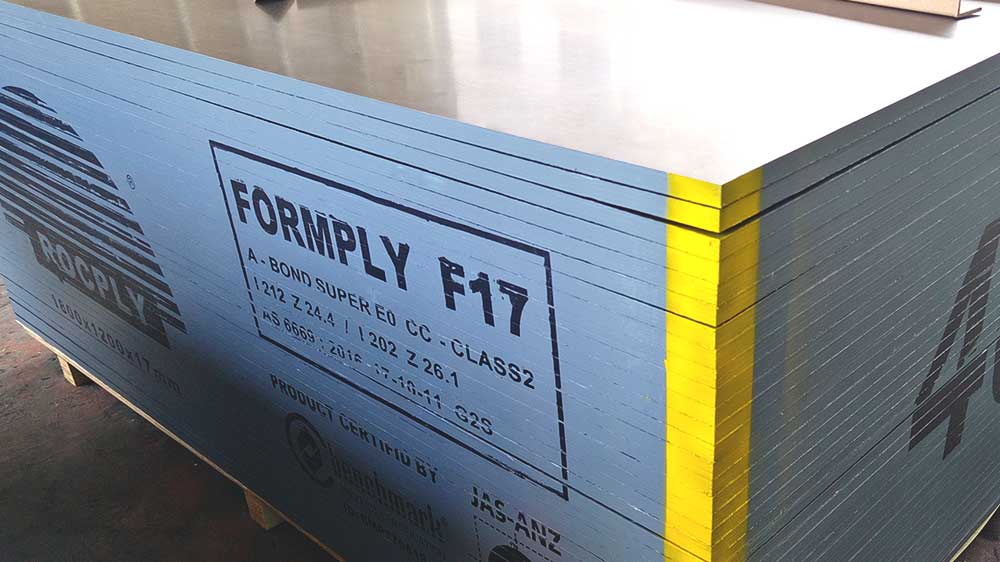

Formply Plywood In a Nutshell

ROCPLY formply is made up of multiple layers of wood veneer, bound together under high pressure. This process imbues it with qualities that are hard to find in a single material—durability, ease of use, and an eco-friendly footprint.

Formply Plywood Material Composition: The Secret Behind Its Robustness

The strength of Formwork plywood doesn’t just come from anywhere. It’s a meticulously designed product.

Formply Plywood Layering Technique

Each layer of wood veneer in Formwork plywood is arranged with its grain perpendicular to adjacent layers. This cross-grain arrangement enhances its strength and stability.

ROCPLY High-Quality Adhesives

The layers are bonded with top-grade adhesives, ensuring a long-lasting union that can withstand various environmental conditions.

A Touch of Innovation

Formply Plywood also often incorporates specialized resins, giving it that extra edge in durability and resistance to moisture and chemicals.

Formply Plywood Environmental Footprint: Being Kind to Mother Earth

As much as we love durable materials, it’s essential that they don’t cost the Earth. ROCPLY formply is a winner in this regard as well.

Formply Plywood Sustainably Sourced

Formwork plywood panels often come from sustainably managed forests, contributing to responsible building practices.

Formply Plywood Recyclability

Another attractive feature is its recyclability. Once its life cycle is over, the material can be repurposed or recycled, further minimizing its environmental impact.

Where Can You Use Formply Plywood? Versatility at Its Best

Formply Plywood isn’t a one-trick pony. Its range of applications is as impressive as its material composition.

Construction Formwork

The most common use of ROCPLY formply is in formwork for concrete structures. Its surface finish ensures that the concrete cast against it comes out smooth and requires minimal additional work.

Flooring and Decking

Not just for vertical structures, Formwork plywood is also an excellent choice for flooring and decking. Its durability ensures it can handle high foot traffic and heavy loads, making it a popular choice for commercial spaces.

Furniture and Cabinetry

Don’t underestimate Formply Plywood when it comes to indoor applications. Its smooth finish and durability make it an ideal choice for furniture and cabinetry as well.

How to Choose the Right Formply Plywood

Selecting the appropriate ROCPLY formply for your project can be a crucial decision. Here are some tips to help you make an informed choice.

Thickness Matters

Formwork plywood comes in various thicknesses, each suited for different applications. Thicker panels are generally recommended for formwork in construction, especially for high-load-bearing walls. For furniture and indoor applications, thinner panels often suffice.

Surface Finish

Formply Plywood is renowned for its smooth surface, a feature vital for concrete formwork. However, there are also textured options available for those who seek a more rustic appearance for decking or flooring.

Certifications and Standards

Always look for the necessary certifications to ensure that you’re buying a high-quality product. FSC or PEFC certifications can be a reliable indicator of sustainably sourced wood.

Workability

ROCPLY formply is generally easy to work with, but it’s always a good idea to consult with the supplier about its suitability for specific applications. Some products are specially treated for resistance to moisture and chemicals, a useful feature for outdoor projects.

Safety and Precautions: Working Smartly with Formply Plywood

Safety should never be compromised, especially when working with construction materials. So what do you need to know when handling Formwork plywood?

Handling and Storage

Always handle Formply Plywood panels carefully to prevent surface damage. They should be stored flat and supported at all times to maintain their shape.

Cutting and Drilling

ROCPLY formply can be cut and drilled using standard woodworking tools. However, ensure that the tools are sharp to prevent surface chipping or splintering.

Personal Protective Equipment (PPE)

Wear appropriate PPE, such as gloves and eye protection, when working with Formwork plywood. While the material itself is safe, the cutting or drilling process can produce wood dust, which can be an irritant.

Formply Plywood Cost-Efficiency: More Bang for Your Buck

One of the most attractive aspects of Formply Plywood is its cost-efficiency. Given its durability and versatility, it offers excellent value for money.

Longevity and Durability

ROCPLY formply lasts for a long time, making it a cost-effective investment. Its high resistance to wear and tear means that maintenance costs are minimal.

Multi-Use Nature

The multi-use nature of Formwork plywood adds another layer to its cost-efficiency. A single panel can often be used in various applications, from formwork to flooring, providing excellent value.

Bulk Discounts

Purchasing Formply Plywood in bulk often comes with the added benefit of discounts, making it an even more attractive option for larger projects.

In the realm of building materials, ROCPLY formply stands out not just for its robustness but also for its cost-effectiveness. By choosing this material, you’re not only opting for quality but also for long-term savings. And who wouldn’t want that?

ROCPLY Environmental Impact: Formply Plywood Green Credentials

With a growing focus on sustainable construction and living, the environmental aspect of building materials has never been more relevant. Formwork plywood addresses these concerns in a variety of ways.

Sustainable Sourcing

Formply Plywood often comes from sustainably managed forests, reducing the environmental impact. Certifications like FSC and PEFC offer assurance that the wood used complies with sustainable practices.

Recyclability

While ROCPLY formply is sturdy and long-lasting, it’s also recyclable. Once its useful life is over, it can be chipped down to create other wood-based products, contributing to a circular economy.

Low VOC Emissions

Formwork plywood usually has low volatile organic compound (VOC) emissions, making it safer for indoor use and less harmful to the environment.

Energy-Efficient Production

Modern manufacturing processes for Formply Plywood often aim for energy efficiency, further minimizing the product’s carbon footprint.

Innovations: The Future of Formply Plywood

Formply Plywood has been around for some time, but innovations continue to make it even more versatile and practical.

Smart Coatings

Recent developments include smart coatings that make the plywood more resistant to moisture, chemicals, and even fire. This makes ROCPLY formply suitable for an even broader range of applications.

Enhanced Aesthetics

As tastes evolve, so do the design possibilities with Formwork plywood. New surface finishes and textures are being introduced, adding aesthetic choices for architects and homeowners alike.

Digital Fabrication

As technology advances, so does the ease of customizing Formply Plywood. Computer-aided design (CAD) and computer numerical control (CNC) machines make it easier than ever to produce intricate designs and custom shapes.

Where to Buy Formply Plywood: Navigating the Market

With numerous suppliers and types of ROCPLY formply, navigating the market can be overwhelming.

Online Vs. Physical Stores

Both online and physical stores have their advantages. Online stores often provide detailed product descriptions and customer reviews, while physical stores allow you to see and touch the product.

Supplier Reputation

It’s essential to research the reputation of the supplier you’re considering. Customer reviews and industry accreditations can offer valuable insights.

Price Comparison

Be sure to compare prices across multiple suppliers to ensure you’re getting the best deal. Remember, though, that the cheapest option is not always the best in terms of quality.

Formply Plywood has been a mainstay in construction and home improvement projects for good reason. With its wide range of applications, environmental credentials, and constant innovation, it’s hard to find a more versatile and reliable material. As such, it should be a top consideration for anyone in the market for high-quality, multi-purpose plywood.

How to Use: Best Practices for Installing Formply Plywood

Getting the most out of your Formwork plywood means understanding how to install it effectively. Let’s explore some best practices that can make your next project a success.

Pre-Installation Planning

Take time to measure and plan before cutting or installing your ROCPLY formply. Accurate planning can save both time and material costs.

Proper Storage

Improper storage can damage Formply Plywood before it’s even used. It should be stored flat and elevated off the ground to prevent warping and moisture damage.

Correct Fastening Methods

Whether you’re using nails, screws, or adhesives, ensure you’re using the proper fastening methods. Consult the manufacturer’s guidelines for best results.

On-Site Adjustments

Sometimes, on-site adjustments are necessary. Portable hand tools like saws and drills can help you make precision cuts and holes, ensuring a perfect fit.

Formply Plywood Safety Guidelines: An Important Note About Formply Plywood

Formply Plywood is generally safe to use, but observing some safety guidelines can prevent unnecessary risks.

Proper Handling

Always handle Formply Plywood carefully to avoid splinters and other potential injuries. Wearing protective gear like gloves and goggles is advised.

Dust and Fumes

Cutting and sanding Formply Plywood can produce dust and fumes. Always work in a well-ventilated area and consider using a mask or respirator.

Chemical Safety

Some types of Formply Plywood may be treated with chemicals for added resilience. Always read the safety data sheets and follow any guidelines for safe handling.

Formply Plywood Common Mistakes to Avoid

Even seasoned professionals can make mistakes. Here are some common errors to steer clear of when using Formply Plywood.

Ignoring Grain Direction

Plywood has a grain direction, which impacts its strength and appearance. Ignoring this can result in a less durable or aesthetically pleasing finish.

Overloading

Formply Plywood is strong but not invincible. Overloading it beyond its weight capacity can lead to failure and may compromise safety.

Using Incorrect Tools

The wrong tools can damage the material and compromise the quality of your project. Always use tools that are well-suited for Formwork plywood.

Poor Finishing

An improper finish can negate many of the benefits of using Formply Plywood. Take the time to apply the correct sealants or paints for your specific application.

Formply Plywood is a material that combines durability, versatility, and sustainability. With proper usage and care, it can meet and exceed your expectations in various applications. Be it construction or furniture, Formply Plywood stands as a remarkable solution for both professionals and DIY enthusiasts.

The Environmental Footprint: A Closer Look

The use of Formply Plywood isn’t just about the robustness or aesthetics; it’s also about contributing to a healthier planet.

Renewable Resource

One of the best things about Formply Plywood is that it comes from a renewable resource: trees. Sustainable forest management practices ensure that this resource doesn’t run out, making it an eco-friendly choice.

Recyclable and Biodegradable

The afterlife of a Formply Plywood sheet is also noteworthy. Once its time is done, the plywood is either recyclable or biodegradable, causing minimal impact on the environment.

Energy Efficiency

The production of Formply Plywood is more energy-efficient compared to many other building materials. Its manufacturing process uses nearly every part of the log, reducing waste.

Formply Plywood Customization Options: Making it Your Own

Formply Plywood doesn’t have to be bland or monotonous. There are various ways to make it uniquely yours.

Choice of Veneers

Different veneers can give Formply Plywood a completely new look. From the elegant cherry to the rustic oak, the choices are plentiful.

Stains and Finishes

You can apply a variety of stains and finishes to Formply Plywood. Whether you prefer a natural look or a more vibrant hue, the possibilities are endless.

Laser Cutting and Engraving

Technological advancements have made it easier than ever to customize Formply Plywood. Laser cutting and engraving can be used to create intricate designs or logos, adding a personal touch to your project.

Frequently Asked Questions About Formpy Plywood (FAQs)

Everyone has questions when it comes to new products. Here’s a roundup of some commonly asked questions about Formply Plywood.

Is Formply Plywood Waterproof?

Yes, but to a certain extent. While it does have water-resistant properties, it is not 100% waterproof.

Can I use Formply Plywood for Exterior Projects?

Yes, but make sure to use exterior grade Formply Plywood which is treated to withstand the elements.

How Thick is Formply Plywood?

Formply Plywood comes in various thicknesses, usually ranging from 1/8 inch to 1 inch. Choose the thickness that suits your specific project needs.

Is Formply Plywood Suitable for Flooring?

While Formply Plywood can be used for subflooring, it’s generally not recommended as the main flooring material unless specifically designed for that purpose.

ROCPLY Formply Plywood is an evolving product that consistently proves its worth. As we’ve outlined, its applications range from simple household projects to complex construction requirements. The beauty of Formply Plywood is that it gives you the freedom to create, while also being kind to Mother Earth. Stay tuned for more updates and new features, as this amazing product continues to evolve.

Post time: Sep-13-2023