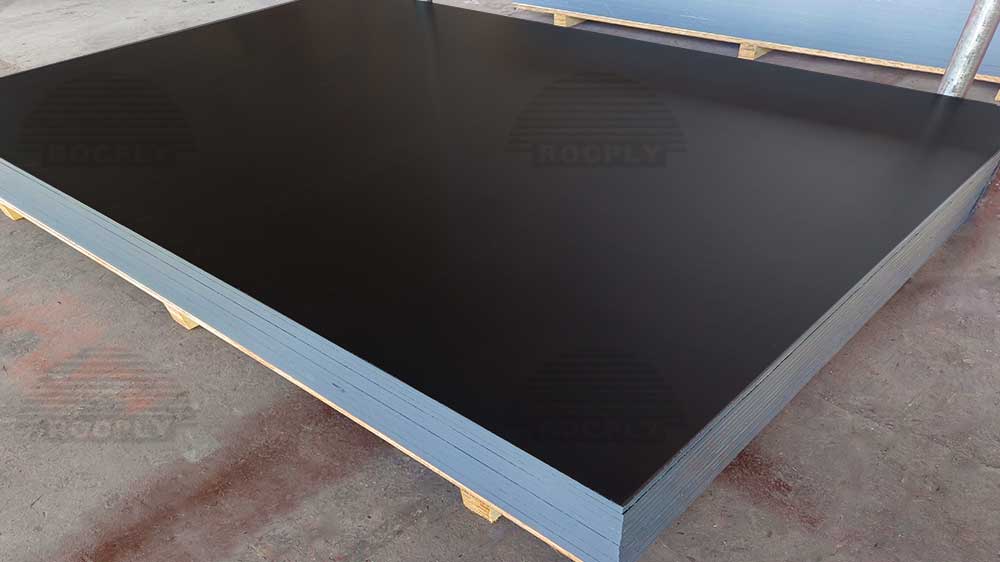

An Introduction to Formply 12mm

Formply, often known as formwork plywood, has firmly established itself in the heart of Australia’s construction scene. When it comes to this material, Formply 12mm emerges as one of the most sought-after dimensions, but why?

The Genesis of Formply in Australia

Australia’s diverse and challenging terrains require building materials that can stand the test of time. Formply, primarily made from a hardwood veneer, was introduced to meet the stringent demands of the Australian climate. Its resilience to harsh environmental conditions and high load-bearing capabilities have made it indispensable.

What Sets the 12mm Variant Apart?

While Formply is available in multiple thicknesses, the 12mm variety is particularly admired for its optimal balance. It’s thick enough to offer robustness without becoming overly heavy, making it a favourite for many construction projects.

Features that Make Formply 12mm Stand Out

With so many building materials available, one might wonder why Formply 12mm gains such a revered position in the Australian market.

Durability and Strength

At its core, Formply 12mm is designed for repeated use without significant wear and tear. Its layers are bound together with strong adhesives, ensuring that it doesn’t delaminate even under pressure. Furthermore, its hardwood nature makes it resistant to dents and chipping, providing longevity.

Resistance to Environmental Factors

One of the striking features of Formply 12mm is its ability to withstand environmental challenges. Be it the scorching Australian sun, heavy rainfall, or even termite attacks, this material has got it covered.

Flexibility in Application

Thanks to its dimensions and strength, Formply 12mm is versatile. From concrete formworks to home renovations and furniture creations, its applications are vast and varied.

Why Professionals Choose Formply 12mm

It’s not just the tangible features of Formply 12mm that have made it a preferred choice. The professionals working with it day in and out have their reasons.

Easy Handling and Workability

One of the primary benefits of film faced plywood 12mm is the ease with which professionals can work with it. Cutting, drilling, or nailing becomes a straightforward process, making it a favourite for quick turnarounds.

Cost-Effective in the Long Run

While there might be cheaper alternatives in the market, Formply 12mm offers cost-effectiveness in the long run. Its durability means fewer replacements, and its resistance to environmental factors reduces maintenance costs.

Consistent Quality

Every sheet of formwork plywood 12mm that reaches a construction site adheres to strict Australian standards. This consistency ensures that professionals don’t have to second-guess their material’s performance.

Formply 12mm in Real-world Applications

Seeing Formply 12mm in action offers a clearer understanding of its pivotal role in the building sector.

High-rise Constructions

Towering structures that grace Australian skylines often rely on Formply 12mm during their foundation stages. The sheets serve as robust moulds for concrete, ensuring precision and consistency in the final structure.

Residential Renovations

Homeowners seeking a blend of aesthetics and strength often turn to form ply 12mm. Whether it’s crafting a new kitchen countertop, constructing a robust deck, or even fashioning custom furniture, this material has been a cornerstone.

Infrastructure Projects

Public infrastructure projects, such as bridges, tunnels, and highways, require materials that can endure. Film faced plywood 12mm, with its resilience and longevity, has been the go-to choice for many of these critical developments.

Caring for Your form ply 12mm

To harness the maximum potential of Formply 12mm, one needs to ensure its proper maintenance.

Regular Cleaning

Like any other building material, Formply 12mm benefits from regular cleaning. Using a damp cloth to wipe off dust and debris not only maintains its appearance but also enhances its lifespan.

Proper Storage

When not in use, it’s essential to store Formply 12mm sheets in a flat, dry area. This simple step prevents warping and ensures the sheets remain in pristine condition for their next use.

Avoid Prolonged Water Exposure

While Formply 12mm boasts water resistance, it’s still wise to avoid prolonged exposure. Ensuring that the sheets are dry before storing them goes a long way in maintaining their integrity.

Environmental Impact and Sustainability

In today’s world, considering the environmental impact of our choices is vital.

Sustainable Forestry Practices

The hardwood veneer that constitutes Formply 12mm predominantly comes from sustainably managed forests. This commitment ensures that we aren’t depleting our precious natural resources irresponsibly.

Recycling and Reusability

One of the prominent advantages of Formply 12mm is its potential for reuse. Rather than discarding used sheets, many construction professionals find alternative applications for them, reducing waste.

Reduced Carbon Footprint

By choosing local Australian-made Formply 12mm, one significantly cuts down the carbon footprint associated with importing materials. This conscious choice not only supports local industries but also contributes to a greener planet.

The Economic Impact of Formply 12mm in Australia

The influence of Formply 12mm isn’t limited to construction sites. It has significant implications for the broader Australian economy.

Job Creation

From the forestry sector to manufacturing and transportation, the demand for formwork plywood 12mm creates jobs across multiple sectors. This ripple effect strengthens the Australian economy, providing livelihoods to thousands.

Boosting Local Industries

The preference for Formply 12mm over imported alternatives has played a role in invigorating local industries. This not only ensures quality control but also circulates money within the nation, fostering economic growth.

Export Opportunities

Given its stellar reputation, form ply 12mm is not just a domestic marvel. Many countries, recognising its superior quality, have turned to Australia as a trusted supplier, opening up new export avenues.

The Future of Formply 12mm

As construction methodologies evolve, how does Formply 12mm fit into the future landscape?

Innovations in Manufacturing

The process of making shuttering plywood 12mm is constantly improving. With technological advancements, we can anticipate even more durable, efficient, and environmentally-friendly variants in the coming years.

Broadening Applications

Beyond traditional construction, there’s potential for film faced plywood 12mm in sectors like interior design, art installations, and more. Its versatility ensures it remains relevant in an ever-changing world.

Commitment to Sustainability

As global consciousness shifts towards sustainable practices, formwork plywood 12mm is set to become even more eco-friendly. From sourcing to production, every stage will likely see further enhancements in sustainability.

Overcoming Challenges

No product is without its challenges, and Formply 12mm is no exception. However, the Australian industry’s proactive approach ensures these hurdles are addressed promptly.

Addressing Price Fluctuations

Like all commodities, form ply 12mm can be subject to price fluctuations. By investing in research, increasing efficiency, and ensuring sustainable practices, the industry aims to provide consistent pricing for consumers.

Meeting Global Standards

As the export market grows, meeting diverse global standards becomes paramount. Continuous quality checks and upgrades ensure shuttering plywood 12mm remains a globally sought-after product.

Tackling Environmental Concerns

While film faced plywood 12mm is already sourced sustainably, there’s always room for improvement. Collaborative efforts between industry stakeholders aim to further reduce the environmental impact.

The Consumer’s Perspective on formwork plywood 12mm

As we delve deeper into the world of Formply 12mm, understanding the consumer’s viewpoint is crucial.

Value for Money

For many, the upfront cost of building materials can be a deciding factor. Consumers have often found that while formwork plywood 12mm might have a higher initial price tag, its longevity and minimal maintenance offer unmatched value over time.

Ease of Availability

With Australia’s robust supply chain, consumers appreciate the ease of accessing form ply 12mm. Whether it’s a large-scale construction or a small home project, this material is readily available.

Trust in Australian Quality

There’s a sense of trust associated with products made in one’s homeland. Consumers feel confident knowing that shuttering plywood 12mm adheres to Australian standards, ensuring both safety and quality.

Form ply 12mm vs. Other Materials

In the vast world of building materials, how does film faced plywood 12mm compare to its counterparts?

Superior Strength

While many materials offer durability, few can match the resilience of formwork plywood 12mm. Its unique composition and manufacturing process give it an edge over many alternatives.

Environmentally Friendlier

In comparison to materials like plastic or metals, which can be ecologically taxing, Formply 12mm emerges as a more sustainable choice. From sourcing to decomposition, its environmental footprint is considerably smaller.

Versatility in Application

Many materials are designed for specific applications. form ply 12mm, on the other hand, boasts versatility that few can rival, making it a multi-purpose champion.

The Journey Ahead for Formply 12mm

The story of shuttering plywood 12mm is one of consistent evolution. With changing times, what lies ahead?

Embracing Technology

The fusion of technology with film faced plywood 12mm manufacturing can usher in a new era. From smart sensors to AI-driven quality checks, the future is brimming with possibilities.

Expanding Horizons

Beyond traditional applications, there’s potential for formwork plywood 12mm to enter uncharted territories. Think space construction, underwater habitats, or even artistic sculptures.

Strengthening Global Presence

As the world recognises the prowess of Formply 12mm, there’s a vast global market waiting to be tapped. By addressing international needs and standards, form ply 12mm can further solidify its global position.

ROCPLY Formply 12mm stands as a testament to Australian ingenuity, quality, and commitment to sustainability. Its journey from local construction sites to global prominence speaks volumes about its unmatched attributes and the trust it has garnered. As we move forward, one thing is clear: Formply 12mm’s legacy in the world of building materials is only set to grow.

Post time: Dec-09-2023