F14 vs F17 Formply

Choosing the right materials for construction projects is crucial for success. In the realm of formwork, F14 formply and F17 formply are commonly discussed options. But which is the better choice for your specific needs? In this in-depth analysis, we’ll explore the key differences between these two grades of formply, from their structural strength to their applications and cost-effectiveness.

F14 vs F17 Formply Structural Strength

F14 formply: The Basic Workhorse

F14 formply is a versatile choice designed for medium-duty applications. Its lower stress grade rating makes it a cost-effective solution for less demanding projects, while still offering adequate strength.

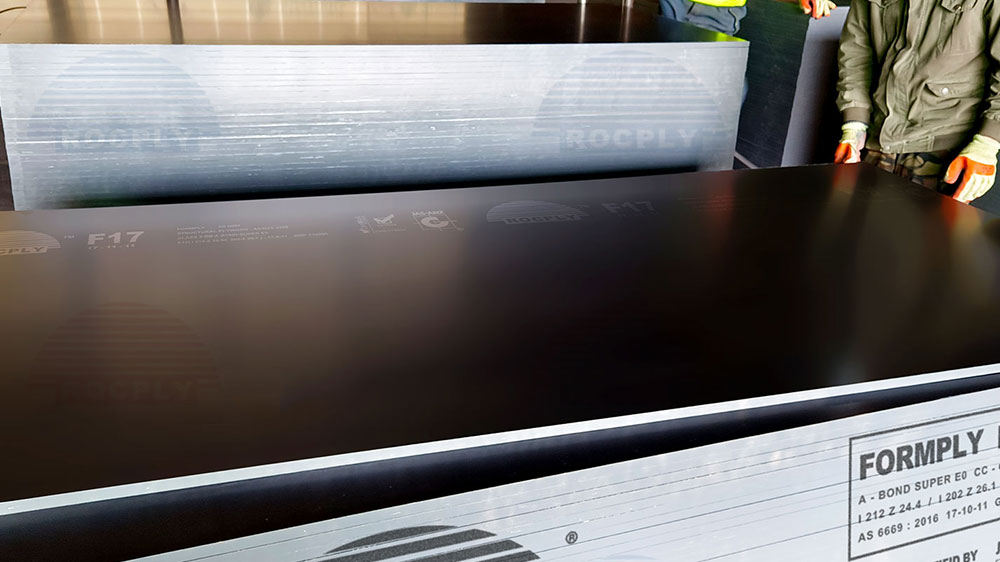

F17 formply: The Heavy-Duty Contender

In contrast, F17 formply is engineered for high-stress environments. It has a higher stress grade, which translates to greater load-bearing capacity, making it a suitable choice for commercial and large-scale construction projects.

F14 vs F17 Formply Material Composition

What Makes Up F14 formply?

F14 formply often comprises of a combination of softwood veneer and a phenolic adhesive. These components are bonded together under high pressure to form a panel capable of sustaining moderate loads.

Core Components of F17 formply

F17 formply typically features a hardwood veneer fused with a high-grade phenolic adhesive, making it more resilient to stress. These superior materials contribute to its heightened strength and durability.

F14 vs F17 Formply Weight Comparison

F14 formply: Lighter on the Pocket and the Scale

Being less dense and usually thinner, F14 formply is generally lighter, making it easier to handle and transport. This weight advantage could translate to reduced logistical costs in some scenarios.

F17 formply: The Robust and Heavier Option

Due to its composition and thickness, F17 formply is inherently heavier. While this means higher transportation costs, the material’s weight is a trade-off for its improved structural capabilities.

F14 vs F17 Formply Cost Implications

F14 formply: Budget-Friendly Option

When the budget is a constraint, F14 formply offers an economical solution. The upfront material cost is generally lower, making it an attractive choice for small to medium-sized projects.

F17 formply: Long-Term Investment

Though F17 formply comes at a premium, it often proves to be a prudent long-term investment. Its higher durability and reusability rates can offset the initial costs over time, particularly for large-scale or long-duration projects.

F14 vs F17 Formply Applications and Usage Scenarios

F14 formply: Residential and Low-Impact Projects

F14 formply is most commonly seen in residential construction, small-scale commercial projects, and applications where the strength requirements are moderate. Whether you’re building a backyard deck, a home extension, or a modest commercial space, F14 formply can be a practical choice.

F17 formply: The Choice for Commercial and Heavy-duty Applications

If you’re in the realm of skyscraper construction, high-rise apartments, or industrial settings, F17 formply becomes the go-to choice. Its load-bearing capabilities and durability make it ideal for such high-impact scenarios.

F14 vs F17 Formply Surface Finish

F14 formply: Good Enough for Most Needs

F14 formply panels usually come with a decent surface finish that’s satisfactory for most low-to-mid-level applications. This is typically adequate for scenarios where aesthetics aren’t a primary concern.

F17 formply: Pristine Surface Finish

F17 formply, on the other hand, offers a smoother, more consistent surface finish due to its higher-quality materials and manufacturing processes. This is especially beneficial when you want your concrete surfaces to have a smooth and clean finish, often seen in premium commercial spaces.

F14 vs F17 Formply Environmental Impact

F14 formply: A Greener Choice?

One might argue that F14 formply, being generally thinner and less dense, has a smaller environmental footprint. However, the overall impact depends on multiple factors, including the sourcing of the wood and the manufacturing process.

F17 formply: Longevity Can Be Green

F17 formply’s durability and potential for reuse can contribute to a lower environmental impact in the long run, especially if sourced from sustainable forests and manufactured using eco-friendly methods.

F14 vs F17 Formply Reusability Factor

F14 formply: Limited but Possible

While F14 formply panels can be reused, their lifespan is shorter compared to F17 formply. This makes them less ideal for projects requiring multiple assembly and disassembly cycles.

F17 formply: Built for Reuse

The robust construction of F17 formply panels makes them more reusable, thus extending their lifecycle. For projects that anticipate frequent reconfiguration, F17 formply’s long-lasting nature can prove to be economically beneficial over time.

F14 vs F17 Formply Customization Options

F14 formply: Standard Solutions

F14 formply usually comes in standardized dimensions and finishes. While this can simplify the decision-making process, it limits customization options.

F17 formply: Tailored to Your Needs

If you need customized panel sizes or special finishes, F17 formply often offers greater flexibility. Many manufacturers provide customization options given its usage in more specialized, high-stress environments.

F14 vs F17 Formply Cost Analysis

F14 formply: Economical for Small Projects

When cost is a significant factor, F14 formply is generally less expensive upfront. Its cost-effectiveness makes it suitable for smaller projects with limited budgets. However, considering its lower durability, one might need to replace it more frequently than F17 formply.

F17 formply: Investment for the Long Run

Although F17 formply is generally more expensive upfront, its longer lifespan and higher reusability make it a cost-effective choice in the long run. It’s an investment that pays off especially well for commercial and high-stress projects where durability is paramount.

F14 vs F17 Formply Regulatory Compliance

F14 formply: Meets Basic Standards

F14 formply is compliant with essential industry standards, making it acceptable for use in most small to mid-level projects. However, it might not meet the stringent requirements for high-risk or heavily-regulated environments.

F17 formply: Rigorously Tested

F17 formply is not only compliant with basic industry standards but often surpasses them. Due to its superior quality, it is usually subjected to more rigorous testing and certification processes, making it a choice that meets and often exceeds regulatory requirements.

F14 vs F17 Formply Availability and Supply Chain

F14 formply: Easier to Source

Given its broad range of applications, F14 formply is often easier to find in local hardware stores and from online suppliers. This ease of availability can speed up project timelines and make sourcing simpler.

F17 formply: Requires Specialized Vendors

F17 formply, due to its specialized nature, is typically not as readily available and may require ordering from specialized vendors. However, the extra effort in sourcing can be justified by its long-term benefits and suitability for complex projects.

The Verdict: F14 vs F17 Formply, Which One is Right for You?

F14 formply: Ideal for Budget-Conscious, Low-Stress Environments

If your project doesn’t require high-stress resistance or a flawless surface finish, F14 formply can be an economical and practical choice.

F17 formply: The Choice for Professionals and Large-Scale Projects

For those involved in professional construction or large-scale projects, F17 formply offers the strength, durability, and versatility needed to meet demanding requirements.

F14 vs F17 Formply Environmental Considerations

F14 formply: Standard Environmental Credentials

F14 formply usually meets the standard environmental credentials required for small projects. However, its lifespan may result in more frequent replacements, potentially creating more waste over time.

F17 formply: Built for Sustainability

In contrast, F17 formply is often produced with a focus on sustainable practices, from sourcing to manufacturing. Its longer lifespan also means fewer replacements, thus reducing long-term waste. The end result is a product that aligns better with modern, environmentally-conscious construction practices.

F14 vs F17 Formply Additional Features

F14 formply: Basic Customization

F14 formply offers basic customization options like thickness variations and some level of surface treatment, which may be adequate for many projects but lacks the range of options that professionals often seek.

F17 formply: Advanced Customization Options

F17 formply often comes with advanced customization options such as specialized surface treatments, custom dimensions, and tailored mechanical properties, providing an added layer of adaptability for unique project requirements.

F14 vs F17 Formply Market Trends

F14 formply: Stable Demand

The market demand for F14 formply remains stable due to its utility in various small and medium construction projects.

F17 formply: Growing Popularity

On the other hand, F17 formply is gaining in popularity especially among professionals and industrial users, reflecting a trend towards high-quality, durable, and sustainable construction materials.

F14 vs F17 formply—A Matter of Project Scope and Goals

In the construction industry, the choice between F14 formply and F17 formply often comes down to the specifics of your project—its scale, budget, and the level of quality required. F14 formply is cost-effective and meets the needs of most small to mid-level projects. F17 formply, while more expensive upfront, offers unparalleled strength, durability, and customizability, making it ideal for larger, more complex projects. Ultimately, both have their place in the construction world, but your project’s unique needs will dictate the best choice for you.

Post time: Sep-23-2023