What is Formply 17mm?

An Introduction to the Essential Material

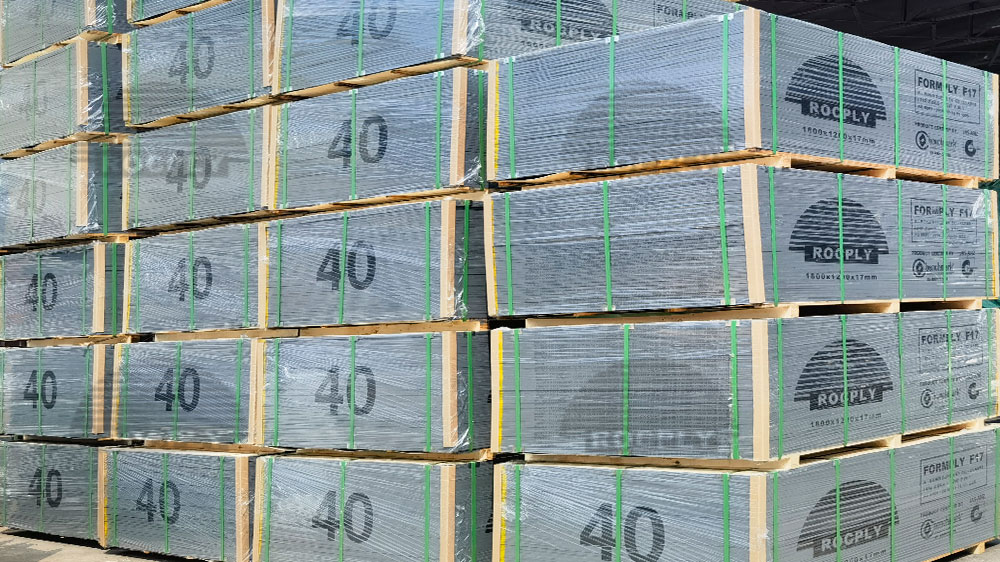

Formply, often recognized as formwork plywood, is a type of plywood designed especially for concrete formwork. Its principal function is to provide a smooth finish to concrete surfaces, ensuring they’re both visually appealing and structurally sound. Among the variety of thicknesses available, the formply 17mm variant has emerged as one of the most popular choices in Australia.

Features that Set it Apart

Made predominantly from hardwood veneer, the formply 17mm is treated with a unique resin, rendering it both water-resistant and durable. Its smooth finish ensures minimal imperfections on concrete surfaces, making it a favourite among builders and architects.

Why Formply 17mm Dominates in Australia

Beyond Just Durability

While it’s true that the robust nature of formply 17mm is a significant selling point, there’s much more to this material than meets the eye. Australia’s unique climate conditions – varying from humid coastal areas to arid interior regions – demand building materials that can withstand such diversities. And formply, especially the 17mm variant, fits the bill perfectly.

Environmental Consciousness

Australia is on the front lines of the global effort to promote sustainable construction practices. The formply 17mm not only excels in terms of performance but also aligns with this ethos. Sourced from sustainable forests, and with manufacturers adopting eco-friendly production practices, this plywood variety ensures that builders do not have to compromise between quality and environmental responsibility.

A Cost-Effective Choice

In the construction industry, cost efficiency is as crucial as the quality of materials used. The formply 17mm provides both. Its long-lasting nature means fewer replacements, and its ability to provide a clean finish reduces the need for subsequent surface treatments. This dual advantage makes it an economically wise choice for both large-scale and smaller projects.

Formply in Australian Architecture

The Rise in Modern Designs

Modern Australian architecture is characterized by its blend of functionality and aesthetics. And with materials like formply 17mm, achieving this balance becomes easier. The smooth finish provided by this plywood has given architects the freedom to experiment with designs, ensuring that concrete structures are not just strong but also visually captivating.

Landmark Projects

From the skyscrapers adorning city skylines to the contemporary homes dotting the coasts, formply 17mm has played a pivotal role in shaping the architectural landscape of Australia. Renowned architects and builders have repeatedly chosen this material for its unmatched reliability and finish.

Delving into the Manufacturing Process

From Timber to Trusted Plywood

The journey of formply 17mm begins in the lush forests where hardwood timber is carefully selected for veneer production. These veneers are then layered, with each layer’s grain running perpendicular to the adjacent one, ensuring optimal strength and stability.

The Role of Resins

A distinguishing feature of formply is the resin treatment it undergoes. The chosen resins make the plywood resistant to moisture, which is crucial for its function in concrete formwork. This resin treatment, coupled with high-pressure bonding, guarantees the plywood’s resilience and longevity, even under challenging conditions.

Ensuring Quality: The Australian Standards

Meeting the AS 6669 Benchmark

Formply 17mm, like other formwork plywoods, needs to comply with the Australian Standard AS 6669. This standard ensures the plywood’s mechanical properties, its resistance to moisture, and its performance under load. Adhering to AS 6669 assures builders and architects that they are working with a product that meets the highest quality benchmarks.

The Importance of Source Verification

While the end product is essential, it’s equally vital to ensure that the materials used are sourced responsibly. Many manufacturers in Australia ensure their formply products, including the 17mm variant, come from certified and sustainable forests. This commitment goes a long way in safeguarding the environment and promoting sustainable building practices.

Formply 17mm in Action: Tips and Tricks

Storing the Material

To maintain the integrity and quality of formply 17mm, it’s imperative to store it correctly. It’s best to keep it flat, off the ground, and under a protective cover to shield it from direct sunlight and rainfall. Proper storage ensures the material remains in optimal condition until it’s time for use.

Working with Formply

While formply 17mm is robust, it’s essential to handle it with care during construction. Using sharp tools ensures clean cuts and minimizes splintering. Furthermore, when fixing the plywood, it’s advisable to space screws or nails evenly and avoid clustering them, which can compromise the material’s structural integrity.

Beyond Construction: The Versatility of Formply 17mm

While the primary use of formply 17mm remains in concrete formwork, its resilience and aesthetic finish have seen it used in various other applications. From furniture designs to interior decorations, the potential of this versatile material is only limited by one’s imagination.

Expanding Horizons: Formply 17mm Beyond Building

Furniture That Stands Out

Thanks to its durability and appealing finish, formply 17mm has become a popular choice among furniture designers. From sleek office desks to modern coffee tables, the unique texture and resilience of formply 17mm offer both aesthetic charm and functional longevity.

Artistic Endeavors

Artists and craftsmen have found a canvas in formply 17mm. The smooth surface is perfect for intricate paintings, carvings, and other artistic applications. Its adaptability allows for a diverse range of projects, from large-scale art installations to smaller decorative pieces.

Maintenance and Care: Ensuring Longevity

Cleaning Formply Surfaces

The best way to keep formply 17mm looking its best is through regular cleaning. Using a damp cloth to wipe away dust and debris helps maintain its shine. For tougher stains, mild detergents can be used. However, it’s essential to avoid abrasive cleaners, which can damage the surface.

Protective Measures

For areas where formply 17mm might be exposed to excessive moisture or potential damage, it’s wise to use protective sealants. These coatings shield the plywood from environmental factors, ensuring its longevity and preserving its aesthetic appeal.

The Future of Formply 17mm in Australia

Embracing Technological Advancements

The construction and design industries are ever-evolving, and so is the production of formply 17mm. Manufacturers are continually seeking ways to enhance the material’s properties, exploring innovative resins and treatments that can offer even greater durability and versatility.

Growing Demand in the International Market

While formply 17mm has cemented its place in Australia’s construction landscape, its reputation is growing on the international stage. Many countries now look to Australia for guidance on sustainable construction practices, and formply 17mm stands as a testament to the nation’s commitment to quality and sustainability.

Addressing Environmental Concerns

Sustainable Sourcing

Given the global push towards sustainability, it’s heartening to see many manufacturers of formply 17mm ensure that their timber is sourced from sustainably managed forests. Such practices not only preserve ecosystems but also assure consumers that they are investing in an environmentally-friendly product.

Recycling and Reuse

End-of-life formply 17mm panels don’t necessarily mean the end of their utility. With proper treatment, used formply can be repurposed for various applications, thus reducing waste and promoting a circular economy.

Reflecting on Formply 17mm’s Legacy and Potential

Paving the Way for Modern Construction

Formply 17mm’s influence on Australia’s architectural and construction domains is undeniable. From skyscrapers to residential projects, this robust and versatile material has enabled professionals to achieve a harmonious blend of strength, functionality, and aesthetics.

Educating the Next Generation

The popularity and importance of formply 17mm in the Australian building sector have also led to educational initiatives. Universities, colleges, and vocational training institutes are increasingly incorporating modules that teach budding architects, designers, and builders about the material’s properties, applications, and best practices.

Building a Sustainable Future with Formply 17mm

A Green Building Revolution

Australia’s commitment to a sustainable future is evident in its construction practices. Formply 17mm, with its sustainable sourcing and potential for reuse and recycling, perfectly encapsulates this commitment. As the country pushes for greener building solutions, formply 17mm will undoubtedly play a pivotal role.

The Global Stage Awaits

Australia’s success with formply 17mm offers valuable lessons for the global construction industry. As more nations seek sustainable and reliable building materials, Australia stands poised to lead, showcasing the benefits of formply 17mm and sharing its expertise with the world.

Formply 17mm: A Deep Dive into Australia’s Favourite Plywood

Formply 17mm isn’t just a building material; it’s a symbol of Australia’s construction prowess and commitment to sustainability. From its humble beginnings in the lush forests to its dominant presence in urban landscapes, it has consistently proven its worth. Whether you’re a builder, architect, designer, or someone curious about construction trends, formply 17mm stands as a testament to what’s possible when innovation meets quality and responsibility.

Post time: Oct-08-2023