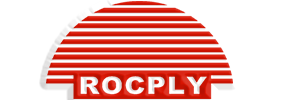

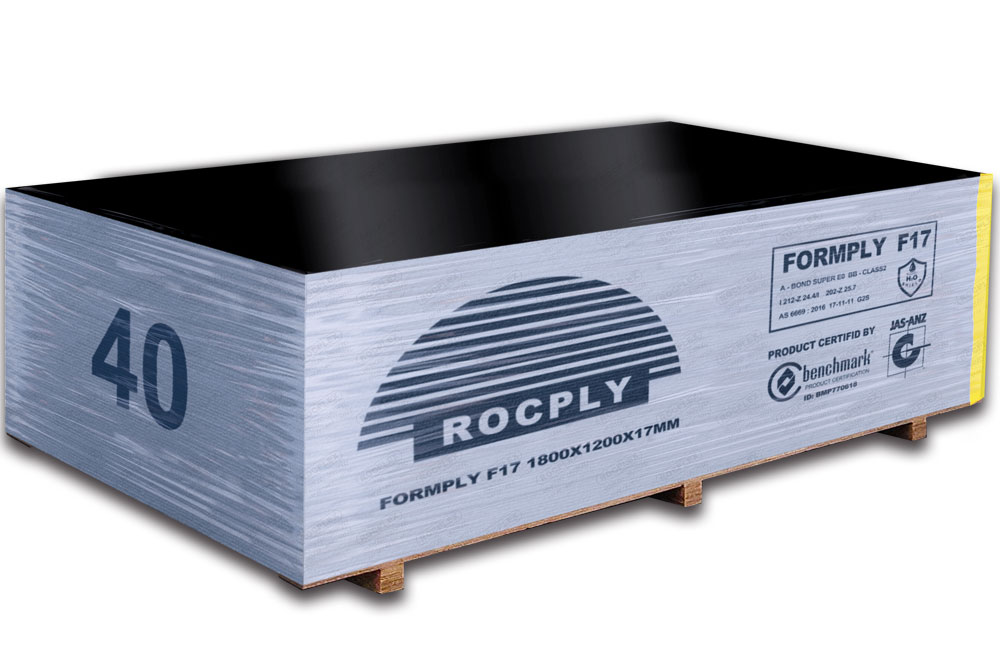

ROCPLY Formply F17

ROCPLY ® F17 Formply is engineered exclusively for the Australian and New Zealand markets. The high-density overlay of phenolic resin film bond delivers a stable, firm form surface finish. Manufactured by SENSO and holding dual certifications, it meets the Australian Standard AS 6669. The product is a breakthrough in construction, providing assurance of quality and consistency.

ROCPLY ® F17 formply formwork plywood showcases excellent stability, offering multiple reuses across various construction sectors. From concrete building to complex structures, ROCPLY structural integrity ensures reliable performance. The Special Custom waterproof HDO surface ensures a robust, smooth finish for first-class concrete quality.

Sustainability is at the heart of ROCPLY production, utilizing veneer hardwood plywood harvested from legally managed, certified forestry plantations. The environmental responsibility extends to the bonding process, where A bond super E0 environmental-friendly waterproof adhesive is used, ensuring resilience even after extended exposure to boiling water.

ROCPLY offers a range of dimensions, from 1800 x 1200 mm to 2400 x 1200 mm, with special dimensions available upon request. The precise manufacturing, coupled with a stringent three-tier quality control program, underscores ROCPLY’s commitment to excellence. With proper care, a high-quality off-form finish can be achieved.

ROCPLY Formply F17 For Strong, Stable, Concrete Formwork

Surfaces Surfaces |

|

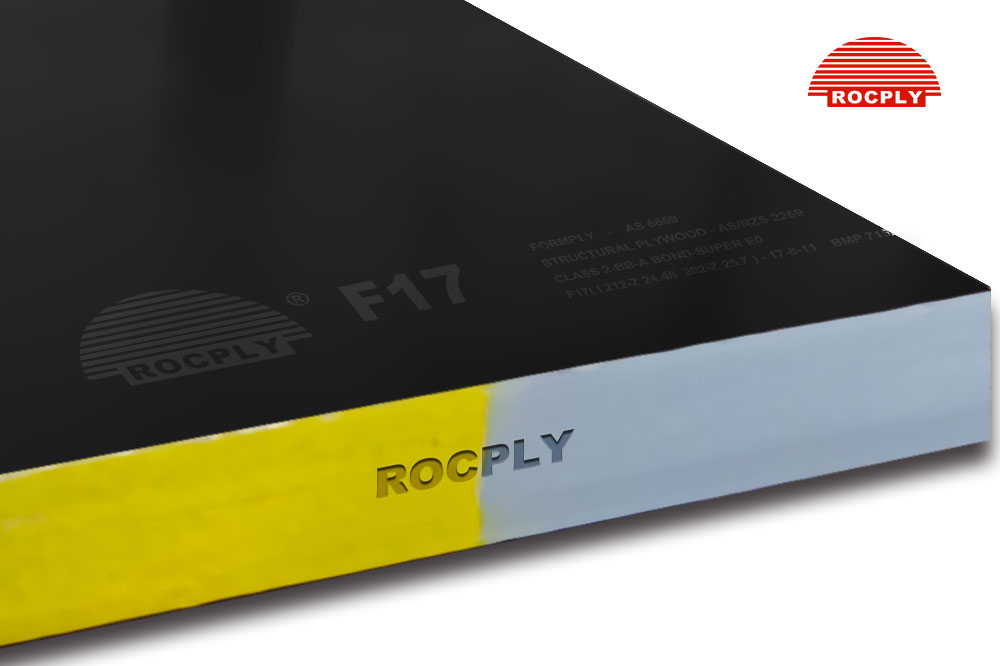

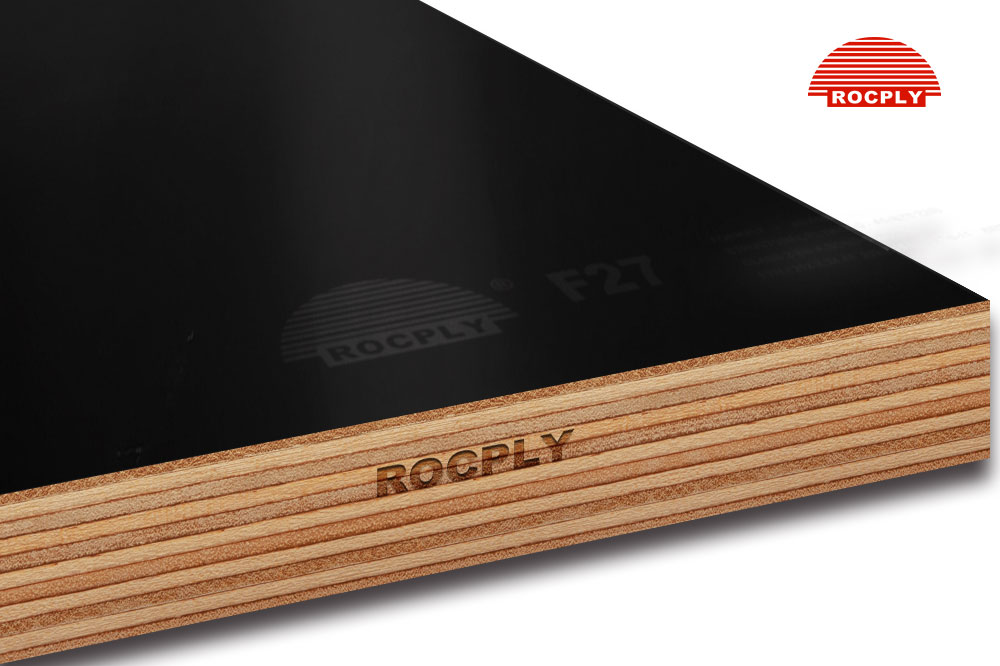

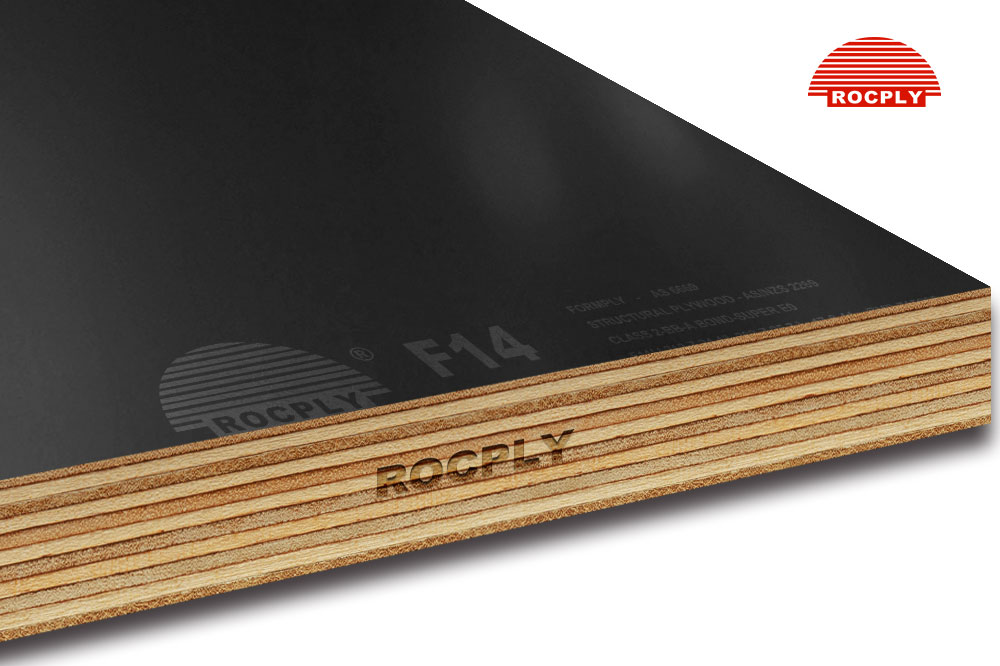

| The special HDO (High-Density Overlay) film facing used in ROCPLY F17 Form Ply provides a super smooth surface designed to resist water absorption and maintain its dimensional stability, which helps prevent the adhesion of concrete during the pouring and setting process. This makes it a durable and reliable choice for concrete formwork applications, even when exposed to moisture or humidity. |

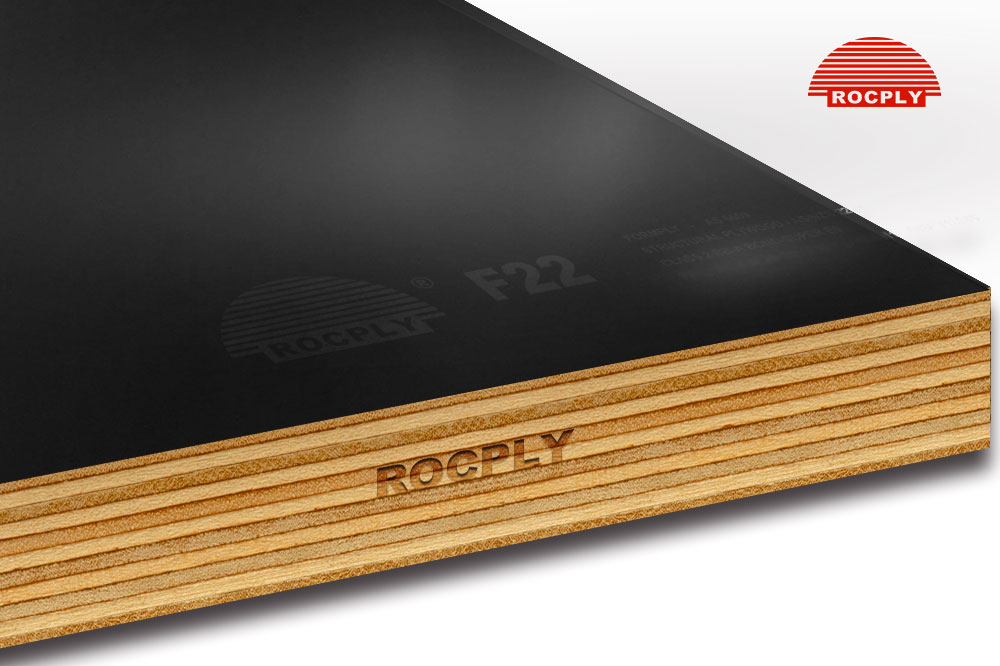

Structure Structure |

|

| ROCPLY F17 made from high-grade full-hardwood veneers, miter joint design, and hot-melt splicing technology making ROCPLY F17 Form Ply a top product is known for its strength and durability, able to withstand the weight and pressure of heavy objects and is less prone to bending, warping or breaking. This helps ensure that the concrete form retains its integrity even after multiple uses. |

Bonding Bonding |

|

| ROCPLY F17 FormPly is made with A-bond Super E0 waterproof adhesive, which is a high-quality adhesive that provides superior bonding strength and water resistance. ROCPLY Laboratory boiling water test data far exceeds 90 hours, it still maintains its glue-sticking properties and will not become deformed. This is a testament to the adhesive used in the ROCPLY manufacturing process, which is able to withstand extreme conditions and remain strong and stable. |

Sealing Sealing |

|

| ROCPLY F17 FormPly is designed with 4 Times sealed edges that are painted with waterproof paint in the factory to minimize moisture penetration. The sealing design helps to prevent moisture and water from penetrating the plywood, which can help to prolong its lifespan and maintain its structural integrity. |

ROCPLY Formply F17 Advantage

Features:

- Surfaces: Special Custom waterproof HDO surface that doesn’t swell or shrink.

- Structural: Manufactured from high-grade full hardwood veneers for hardness and stability.

- Bonding: Bonded with A bond super E0 environmental-friendly waterproof adhesive.

- Sealing: Edges sealed four times with waterproof paint for minimal moisture penetration.

- Sustainability: Sourced from FSC and PEFC certified sustainable forests.

Benefits:

- Durability: Ensures multiple reuses across construction industries.

- Quality Assurance: Regular testing and certification by Certemark and Benchmark.

- Eco-Friendly: Utilizes hardwood from sustainable forestry plantations.

- Versatility: Suitable for various applications including decks, precast, and tilt-up panel construction.

- Customization: Offers special dimensions by request.

Formply F17 FAQ

Q: What is ROCPLY Formply F17?

A: ROCPLY Formply F17 is a high-quality formwork plywood developed and engineered specifically for the Australian and New Zealand market. It is constructed from mixed species veneers with a hardwood face and phenolic overlay. It is ideal for general formwork use such as decks, precast, and tilt-up panel construction.

Q: What sets ROCPLY Formply F17 apart from other plywood products?

A: ROCPLY Formply F17 boasts a high-density overlay (HDO) of phenolic resin film bond, providing a stable surface finish. It also showcases excellent stability, offering multiple reuses across various construction sectors.

Q: Does ROCPLY support OEM/ODM service?

A: Yes, ROCPLY is a one-stop wholesaler that provides OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. We work closely with our clients to customize products that meet their specific requirements and standards.

Q: How is the quality of ROCPLY Formply F17 assured?

A: ROCPLY Formply F17 undergoes a stringent three-tier quality control program comprising: a detailed ‘Manufacturing Specification’ adhered to by trained staff; regular, detailed and recorded in house testing on key quality requirements; and independent grading and testing carried out by Certemark and Benchmark.

Q: Can ROCPLY Formply F17 be reused?

A: Yes, ROCPLY Formply F17 is designed for multiple reuses across the concrete, building, and construction industries due to its excellent durability and structural integrity.